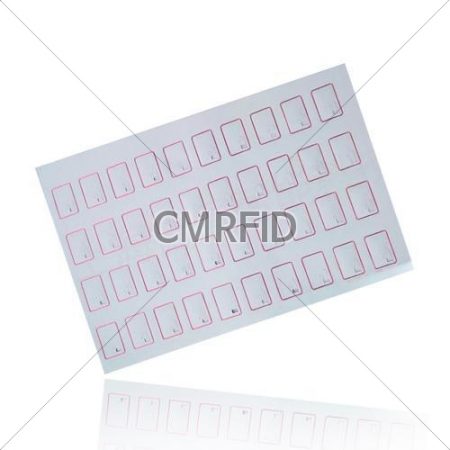

PVC Sheet Inlay

Overview

As core part of RFID card, we provide high-quality RFID inlay which they are suitable to ISO standard cards and made into different thickness and various shape for option.

We have advanced ultrasonic technology, and aluminum (AL) etching techniques, so the quality of our products is not only stable also durable and better Reading and writing performance.

What’s more, the products with the AL etching that can be extreme thin, suitable for special needs.

With customers of more than 30 countries, C&M can offer you various RFID products with superb quality, cost-effective price and fast delivery!

We also welcome our customers to consign chips to us for final card/label production in China.

| Applications | Key Features | ||

| RFID Semi-products for Card Manufactory | Covered all RFID Prelam frequency LF, HF and UHF; | ||

| Automated fare collection | Customized formats and chips available; | ||

| Identification | Highest mechanical durability and lifetime | ||

| Access control | High yield rates in card production | ||

| ePayment | Can be processed with standard card manufacturing

equipment |

IC for option:

TK4100 (125 KHz, 64bit, R/O)

EM4200/EM4102 (125 KHz, 64 bit, R/O)

T5567/T5577 (125 KHz, 330 bit, R/W)

I Code SLI (13.56 MHz, 1024 bit, R/W, ISO 15693 & ISO/IEC 15693)

Mifare 1K/MifareS50 (13.56 MHz, 1K Byte, R/W, ISO 14443 A)

Mifare 4K/Mifare S70 (13.56 MHz, 4K Byte, R/W, ISO 14443 A)

Mifare Ultralight(13.56 MHz, 512 bit, R/W, ISO 14443 A)

Mifare Ultralight C(13.56 MHz, 192 Byte, R/W, ISO 14443 A)

Mifare Desfire EV1(13.56MHZm2K/4K/8K byte,R/W,ISO 14443 A)

combi inlay with Mifare 1K + EM4200.

| Operating Frequency | LF 125KHz, HF 13.56MHz, UHF GLOBAL 860MHz-960MHz | ||

| Standard | ISO14443,ISO15693,ISO 18000 | ||

| Material | PVC, PET | ||

| Dimension | 310mm x 468mm, Max. size 520mm x420mm, A4 210mm x297, | ||

| Layout | 3×7, 5×5,3×8,4×8,4×6, 2×5,2×4,

or any Customization of CR80 card or any unit antenna size |

||

| Thickness | HF normal 0.45mm,0.5mm, min.0.3mm , | ||

| LF normal ,0.6mm, Min. 0.5mm | |||

| UHF 0.6mm, 0.5mm | |||

| Antenna | HF: AL Etching,Pre-winding Copper coil, Altrasonic Embeding; | ||

| LF: Pre-winding Copper Coli, AL Etching; | |||

| UHF: AL Etching | |||

| Bonding | LF: Wire Bonding, | ||

| HF: FLIP chip, Wire Bonding, MOA2, | |||

| UHF: FlIP chip | |||

| Read range | more than 50mm with our reader | ||

| Working temperature | -25°C ~ +55°C | ||

| Store temperature | -25°C ~ +65°C | ||