Why is it important to Know the Difference Between HF and UHF for Your Application?

It is vital to understand the individual performance, capabilities, strengths, weaknesses and application suitability of HF and UHF, when choosing between these two technologies. By examining the various operating principles and potential environmental concerns, manufacturers can make an informed decision prior to implementing any track and trace technology.

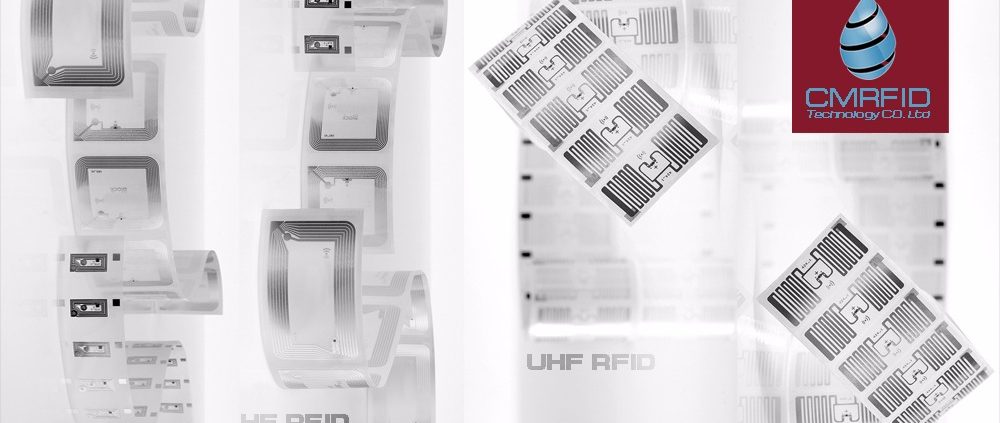

Water, carbon and other materials absorb UHF energy. This means that products containing a high water or carbon content can impact the reliability of the signal. Therefore, when implementing RFID in and around liquid-bearing or carbon-composed products, high-frequency tags are better suited due to their resistance against liquid absorption. Further, when selecting RFID, understanding metal susceptibility is also important. HF tags have a shorter maximum range and are more reliable on an object made of metal. Alternatively, UHF frequencies typically offer better range and can transfer data faster than low and high frequencies, but use more power and are less likely to pass through materials.

Another consideration when selecting the appropriate frequency for a corresponding application is the amount of electromagnetic interference (EMI). EMI is noise that can make it more difficult to obtain a clear signal and can be caused by a wide range of machines. Motors emit EMI and may need to be shielded to prevent interference with RFID systems. Conveyors with nylon belts and robots on assembly lines also cause interference in manufacturing processes.

Also important, RFID must adhere to individual restrictions imposed by each country. For HF, the same technology is accepted worldwide, but UHF frequencies differ depending on region.

Leave a Reply

Want to join the discussion?Feel free to contribute!